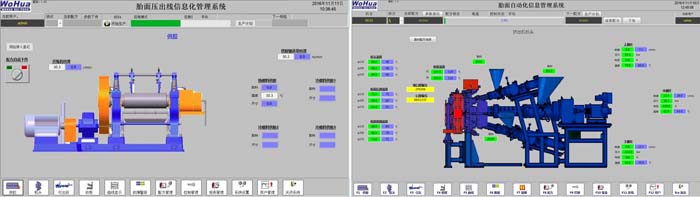

Automatic information management system for tread outlet line

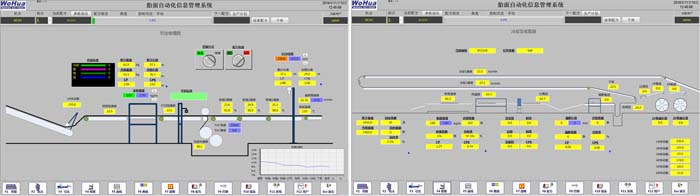

Automatic information management system for tread outlet line

The automatic information management system of tread extrusion line is a set of production automation control system, and also a set of expert knowledge base system with intelligent management. The system is based on large-scale relational database and real-time database, integrates B/S, C/S and intelligent client as one of the system architecture, and adopts object-oriented technology. The unified platform integrates management functions such as production scheduling, formula management, quality control, equipment failure analysis, network reports and so on. The unified database and network connection can provide workshop management information services for the management department, production department, quality inspection department, process department and maintenance department at the same time.

The system consists of information computer system, database, open mixer PLC, extruder PLC, linkage line PLC, width measurement, weighing, code printing, cutting, collecting and other equipment. The production plan is received from the upper MES, and the process formula is transferred to each equipment according to the production plan to complete the automatic production function of the whole production line.

Planning Objectives and basic principles:

1) Objectives of system planning: product quality traceability, automation of production process, intelligent manufacturing control, informationization of production management and network of system structure;

2) Principles of system construction: equipment control safety principle, system interface opening principle.

System Functions:

1) to preset and control of pressure out of the input parameters, the main parameters are: specifications, sizing, mouth number, screw speed, which leads to the speed, mixing machine, heat conveyor belt speed, feed velocity, tread width, rice glue for weighing, individual weight, the length of a single, tire car, color line, action of tolerance and release of tolerance, etc.;

2) Reserve bar code scanning interface to realize automatic formula loading and automatic switching functions;

3) Measure the tread width, meter weight, tread weight, tread length and TUC film width, and control the tread width and weight;

4) Automatic calculation function: production number, length, weight, pass rate, and CPK calculation;

5) Data storage: data storage capacity of more than one year.

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:m.yinheadv.com

Web:m.yinheadv.com