Mixer electrical control system

Mixer electrical control system

Through the combination of the introduction of technology and independent research and development of the production of the MILIAN electromechanical control system, with the international advanced, domestic leading technical level. Can support 80, 110, 160, 255, 270, 370, 400, 620 and other all series and models of mixer.

The combination of the mixer development and production of electrical control system, through the introduction of technology and independent research and development with the international advanced level of leading technology. Can of supporting 80,110,160,255,270,370,400,620 all series and models of mixer. Mixing control system offers a variety of means of communication (PROFIBUS, TCP / IP, DeviceNet, etc.) connected with upper auxiliary and under auxiliary, provide each other with all the production parameters and technical data, the true meaning of the batch production automation. Mixer control system with a number of auxiliary and lower auxiliary equipment suppliers have good cooperation. Mixing control system put into use in a large number of Henan Fengshen and Taiyuan Double Happiness, quality performance and good service access to users praise.

The internal mixer control system is divided into a total of three parts: the control unit of sub-control section and water temperature control section.

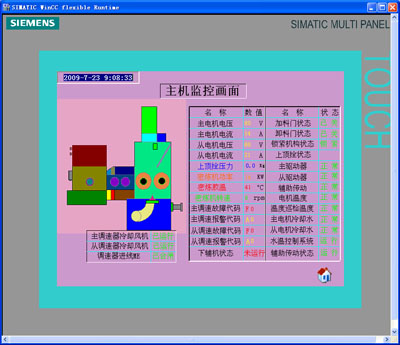

1, the host control section:

● Control system drive control using digital DC speed control, double-loop control can smoothly control the speed at 0-60 rpm.

Relatively independent process operation. Field engineers can manually under top tied on top tied and charging door action to complete the work of the governor and regulator. Tied to the top of the automatic nowadays, on top tied and feeding door action and the governor and regulator entirely on auxiliary controlled by the formula.

● The mixing time is set automatically. Field engineer can be automatically set according to the different type of plastic mixing time of completion of the control chain, the control system automatically after the time expires.

● production safety barrier material control. If the fault does not deal with a serious failure in the workshop batch production process, delay shut down, and prevents the production of the next cars expected, the failure to eliminate the host before normal operation.

Upper and lower auxiliary seamless connection. Mixing system in the normal production can be coordinated to work, the next auxiliary and auxiliary failure, the host control system can still be done manually tune carbon black, fuel adjustment, the gel material, production workshop can still complete the refining plastic flow.

● fault with the manufacturing process chain. If a serious fault occurs in the normal production process, on-site touch-screen instructions and start the sound and light alarm, then, if the fault does not deal with the delay stop, failure to eliminate the host before normal operation. Host shut down to protect the water temperature, transmission and various process conditions have chain control.

The internal mixer control system is divided into a total of three parts: the control unit of sub-control section and water temperature control section.

1, the host control section:

● Control system drive control using digital DC speed control, double-loop control can smoothly control the speed at 0-60 rpm.

Relatively independent process operation. Field engineers can manually under top tied on top tied and charging door action to complete the work of the governor and regulator. Tied to the top of the automatic nowadays, on top tied and feeding door action and the governor and regulator entirely on auxiliary controlled by the formula.

● The mixing time is set automatically. Field engineer can be automatically set according to the different type of plastic mixing time of completion of the control chain, the control system automatically after the time expires.

● production safety barrier material control. If the fault does not deal with a serious failure in the workshop batch production process, delay shut down, and prevents the production of the next cars expected, the failure to eliminate the host before normal operation.

Upper and lower auxiliary seamless connection. Mixing system in the normal production can be coordinated to work, the next auxiliary and auxiliary failure, the host control system can still be done manually tune carbon black, fuel adjustment, the gel material, production workshop can still complete the refining plastic flow.

● fault with the manufacturing process chain. If a serious fault occurs in the normal production process, on-site touch-screen instructions and start the sound and light alarm, then, if the fault does not deal with the delay stop, failure to eliminate the host before normal operation. Host shut down to protect the water temperature, transmission and various process conditions have chain control.

2, the auxiliary control section:

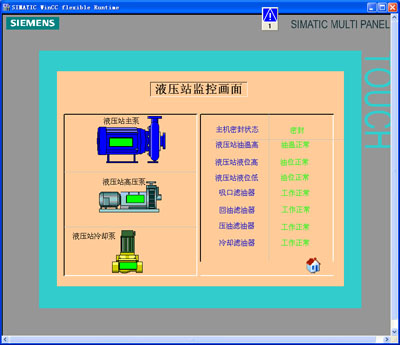

● hydraulic Station control. Hydraulic the station mixing system power source to provide power for the top bolt and the operation of the hopper. The hydraulic station main pump the star start triangle running control mode, the main pump overload protection thermal relay; hydraulic station high-pressure pump and cooling started directly control, the protection circuit breaker with thermal protection.

● control of the system fan and an auxiliary pump. Host fan, gear pumps, lubrication pumps, process pumps and dry pumps have power standard control mode. Control modes include direct start, soft-start and frequency conversion, the user can be customized site different technical requirements appropriate control.

● hydraulic Station control. Hydraulic the station mixing system power source to provide power for the top bolt and the operation of the hopper. The hydraulic station main pump the star start triangle running control mode, the main pump overload protection thermal relay; hydraulic station high-pressure pump and cooling started directly control, the protection circuit breaker with thermal protection.

● control of the system fan and an auxiliary pump. Host fan, gear pumps, lubrication pumps, process pumps and dry pumps have power standard control mode. Control modes include direct start, soft-start and frequency conversion, the user can be customized site different technical requirements appropriate control.

Mixing system water temperature control mixing rotor circuit, the circuit of the mixing chamber and the top bolt loop to provide a heated water supply.

● standardized piping design. The temperature control system design of the principle of using hot water circulating water feed pipe, the system uses the completion of the heater, the heat exchanger and circulation pump hot and cold water circulation. Reasonable distribution of water supply piping components, simple structure, easy installation and maintenance.

● automatically adjust the temperature according to changes in the environment. Temperature control system according to the temperature value set by the user self-tuning adjustment of the ratio of the hot and cold water, to each loop thermostat water supply, to ensure the safe and stable operation of each circuit.

● equipment for the water supply system to provide security. Water cycle process in order to ensure the normal operation of the control system for real-time monitoring of the pressure and flow rate of each loop, when the pressure is too small or when the system automatically performs protect the operator in time to stop the circulation pump run concurrent sound and light alarm. If the water supply system is running water pressure is less than the set value, the water temperature control system will immediately provide electrical protection.

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:m.yinheadv.com

Web:m.yinheadv.com