Air spring forming machine

Air spring forming machine

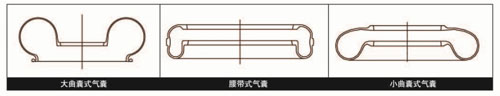

Rubber air spring is a paste made of rubber, cable synthetic curved capsule. The capsule opposite ends required two steel plates connected to form a compressed air chamber. The rubber cable itself does not provide the load bearing capacity, but by the compressed air filled capsule. Used in various fields such as cars, trains, industrial machinery, shock absorption, cushioning role.

Molding machine of the air spring rubber air spring semi-part guide to open, cutting, laminating, compacting, molding, completed the air spring blastocyst forming a composition of sets of equipment are generally divided into: the period molding machine, Sec molding machine and belt molding machine.

The molding of the the ditty capsule airbag only time molding the to fit molding process, a molding machine. The forming need points Daqu capsule airbags secondary complete fit, Sec molding machine molding a molding machine.

1 a molding machine

For a molding machine in a fit and molded into one structure, applicable to cylindrical molding head, conveying different types of cord through the feed frame, fit, compaction, buckle circle and then the process requirements, turn-pressure synthetic , it is convenient to complete a variety of air spring finished production. The device is the finger being package, the bladder turn the structure, the steel ring positioning accuracy, ply package is shrink uniformly, turnup dense finishing. PLC automatic control and touch-screen technology, automatic control and operation of manual, semi-automatic and fully automatic program control. AC servo control, increase the man-machine interface, and can monitor every step sequencer links, and for storing a variety of specifications data at any time parameter modifications to adjust more easily and also have equipment fault diagnosis and prompt. Available random access operation, maintenance and instructions for use I / O the remote forwarding information.

2, belt molding machine

The belt setting machine mainly used for the belt airbags middle rims of molding. Belt setting machines bead placed two half rings, bead pass, chuck, pressure roller group, the overall base, pneumatic pipe system and electrical control system components. The device is the use of the two halves of the ring structure, middle Rims accurate, effective and ply compaction. PLC and touch screen technology in the area of automatic control, to improve the level of automation equipment, reduce labor intensity of production workers, and to ensure the continuous production of the product quality. Host servo motor control to ensure the accuracy of the fit, the touch screen can monitor every step sequencer links, and can be stored in a variety of specifications data for call up at any time, modifications of parameters to adjust more easily and also has equipment fault diagnosis prompts. Available random access operation, maintenance and instructions for use I / O the remote forwarding information.

Technical Specifications

# 1Machine

The molding head diameter range: Ф240 ~ Ф750mm

Buckle circle diameter range: Ф200 ~ Ф650mm

The molded nose width range:150 ~ 650mm (the nose width max50 adjustable)

The molding head center ring adjustment range: Max 50mm

Spindle center height: 900mm

The molding head centerline to the front of the chassis surface: 1100mm

Roller pressure adjustment range: 0.20 ~ 0.35MPa

Supply cord volume width: 350 ~ 1100mm

Maximum diameter of the supply cord volume: 400mm

Ply width: 250 ~ 1000mm

Ply feed axis dimensions: 30 × 30mm

The doily reel size: 30 × 30mm

Dimensions (length X width X height): 4550X5200X2500mm

# 2Machine

The molding head diameter range: d3: Ф280 ~ Ф380mm d4: Ф450 ~ Ф800mm

The molded nose width range: 150 ~ 650mm

Spindle center height: 900mm

The molding head centerline to the front of the chassis surface: 1100mm

Roller pressure adjustment range: 0.20 ~ 0.35MPa

Dimensions (length X width X height): 2050X5200X2500mm

# 3Machine

Bead lock drum diameter range: Ф240 ~ Ф750mm

Bead lock drum width range: 150 ~ 650mm

The intermediate bead diameter range: Ф240 ~ Ф850mm

Spindle center height: 940mm

The molding head centerline to the front of the chassis surface: 1100mm

Roller pressure adjustment range: 0.20 ~ 0.35MPa

Spindle speed: 30 ~ 160rpm

Dimensions (length X width X height): 2050X4500X2200mm

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:m.yinheadv.com

Web:m.yinheadv.com